Our DOT push-in fittings are strong, lightweight, impact resistant and save up to 75% in assembly time compared

to conventional fittings. These meet D.O.T. FMVSS 571.106 Air Brake Performance Requirements;

SAE J1131, J2494-1 & J2494-3 Air Brake Performance Requirements.

Fittings are designed to handle 200 psi working pressure.

RANGE:

| TUBE | PART NO. |

| 1/8" | ABI62000 |

| 5/32" | ABI62001 |

| 3/16" | ABI62002 |

| 1/4" | ABI62003 |

| 3/8" | ABI62004 |

| 1/2" | ABI62005 |

| 5/8" | ABI62006 |

PRODUCT FEATURES:

- Positive Seal - Tube support area beyond “O” ring exceeds that of all competitive products, compensates for bias cut tubing and dramatically reduces troubleshooting time.

- Swivel and Fixed Elbows and Tees - Convenient swivel threaded fittings that allow close center line installation, eliminating orientation problems. Fixed fittings offer the utmost in economy.

APPLICATIONS:

- Air brakes

- Air tanks

- Air ride

- Sliders

- Tire inflation

- Primary & secondary air lines

HOW TO USE DOT PUSH-IN FITTINGS:

DOT push-in fittings are designed for easy use and fast installation.

To connect tube:

Cut the plastic tubing as squarely as possible. Insert the tube into the fitting until you feel the friction as the tube slides past the O-ring. (Using a slight twisting motion while inserting the tube often helps.) Once you feel this friction, continue to push the tube inward until it bottoms firmly against the internal tube stop.

To disconnect tube:

With thumb and forefinger, hold the top of the insert down against the fitting body and, with the other hand, pull out the tubing. No tools are needed.

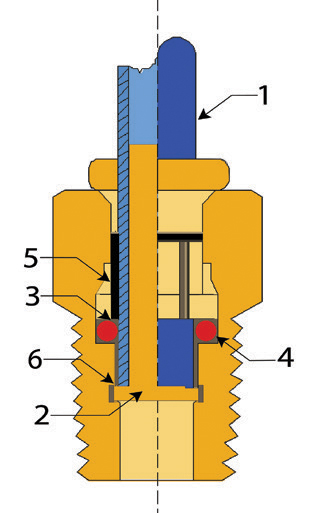

- When tubing (1) is inserted into the fitting, the inside diameter passes over

the brass tube support (2). - This, combined with the action of the gripper, insures that the air brake

hose assembly will safely exceed the tensile requirements of FMVSS-106. - The tubing then passes through the gripping teeth (3).

- The tubing continues beyond the gripping teeth through the inside diameter of

the lubricated “O” ring (4) which seals on the outside diameter of the tubing. - The gripping teeth grab the tube. Pulling back on the tube only tightens the grip

on the tubing as the insert moves onto the camming surface (5). - Pressure through the tube also serves to tighten the grip.

- The tube bottoms against a positive tube stop (6) in a cavity which keeps tube

round toprevent leakage.

Imperial Tube Connector - Straight

- Product Code: ABI62000 to ABI62006

- Availability: In Stock

- $13.20

-

$11.33

- Ex Tax: $10.30